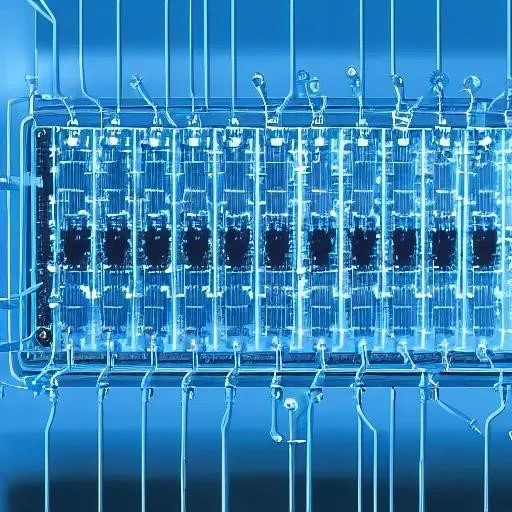

The hum of machinery, once a comforting symphony of progress, now carries a subtle undertone of anxiety. Industrial automation, the backbone of modern manufacturing and critical infrastructure, is increasingly reliant on interconnected digital systems. While this connectivity fuels unprecedented efficiency and innovation, it also opens doors to sophisticated cyberattacks that could cripple operations, endanger lives, and destabilize entire economies. Addressing this critical vulnerability requires a fundamental shift in approach, moving from reactive patching to proactive, integrated cybersecurity strategies that are as dynamic and resilient as the industrial systems they protect. The stakes are undeniably high, demanding immediate and sustained attention from industry leaders, policymakers, and cybersecurity experts alike.

Consider the chilling example of the 2015 Ukrainian power grid attack. Malicious actors infiltrated the supervisory control and data acquisition (SCADA) systems, plunging hundreds of thousands of homes into darkness. This event served as a stark wake-up call, demonstrating the real-world consequences of inadequate cybersecurity in industrial control systems. Today, the threat landscape is even more complex, with the rise of ransomware, state-sponsored actors, and increasingly sophisticated attack vectors targeting everything from oil refineries to water treatment plants. Fortunately, advancements in artificial intelligence, machine learning, and threat intelligence are offering powerful new tools to defend against these evolving threats, promising a more secure and resilient future for industrial automation. The challenge lies in effectively deploying these technologies and fostering a culture of security across the entire industrial ecosystem.

| Topic | Details |

|---|---|

| Industrial Automation Cybersecurity Challenges | Legacy systems often lack built-in security. Complex, interconnected networks increase attack surfaces. Skilled cybersecurity professionals are in short supply. Budgetary constraints limit investment in security measures. A lack of clear industry standards and regulations hinders progress. |

| Key Technologies for Enhanced Security | Intrusion Detection Systems (IDS) and Intrusion Prevention Systems (IPS) provide real-time threat monitoring and response. Security Information and Event Management (SIEM) systems aggregate and analyze security data. Network segmentation isolates critical systems. Endpoint detection and response (EDR) protects individual devices. AI-powered threat detection identifies anomalous behavior. |

| Best Practices for Implementation | Conduct regular risk assessments to identify vulnerabilities. Implement a layered security approach, combining multiple defensive measures. Develop incident response plans to mitigate the impact of attacks. Provide comprehensive cybersecurity training to employees. Enforce strong authentication and access control policies. Regularly update software and firmware to patch vulnerabilities. |

| Industry Examples of Successful Security Implementation | Siemens offers a comprehensive portfolio of industrial cybersecurity solutions and services. Rockwell Automation integrates security features into its automation platforms. Honeywell provides cybersecurity solutions for critical infrastructure. |

| Reference Website | CISA Industrial Control Systems |

By integrating AI-driven insights, we can proactively identify and neutralize threats before they can cause damage. For example, machine learning algorithms can analyze network traffic patterns to detect anomalies that might indicate a cyberattack, remarkably improving response times. Furthermore, the adoption of zero-trust security models, where no user or device is implicitly trusted, strengthens defenses against insider threats and lateral movement within the network. This approach demands continuous verification of identity and authorization for every access attempt, significantly reducing the potential impact of a successful breach. Embracing these advanced technologies and security paradigms is not merely an option; it is an imperative for safeguarding the future of industrial automation.

Looking ahead, the convergence of cybersecurity and industrial automation promises a future where connected systems are inherently secure and resilient. This future requires a collaborative effort, involving government, industry, and academia, to develop robust standards, promote best practices, and cultivate a skilled workforce. Moreover, fostering a culture of security awareness, where every employee understands their role in protecting critical infrastructure, is paramount. By embracing innovation, investing in security, and fostering collaboration, we can unlock the full potential of industrial automation while mitigating the risks that accompany its increasing complexity. The future is being built now, and securing it requires our unwavering commitment to cybersecurity.